Calculating conductor size is very important to the electrical and mechanical properties of a bus bar. Mechanical considerations include rigidity, mounting holes, connections and other subsystem elements. The following tables have been provided by the Alliance for Telecommunications Industry Solutions (ATIS), TCommittee, and represent ampacities for busbar sizes and arrangements typically found in the telecommunications industry. So to calculate the ampacity of any bus bar, envision a cross section of the bar.

Aluminum to copper comparison chart link also. Length is not a factor in the calculation. In reality the ampacity of a single bus bar is not a constant per square inch. Cross-sectional area and the length determine bus bar conductor size.

A value of approximately 4circular mils per ampere is a traditional basis for design of single conductors. If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, we will contact you within one business day. Vertical bar ampacity based on work by House and Tuttle. Horizontal bar ampacity from industry sources. When figuring the ampacity of busbar , most of the I find are.

For large installations requiring millions of pounds of metal, bus system designers have used the low cost of aluminum as the basis for optimum economic cur rent density. Example: Calculate Size of Bus bar having Following Details. Glad To Help With Technical Questions. Send Me a Quote in Business Day!

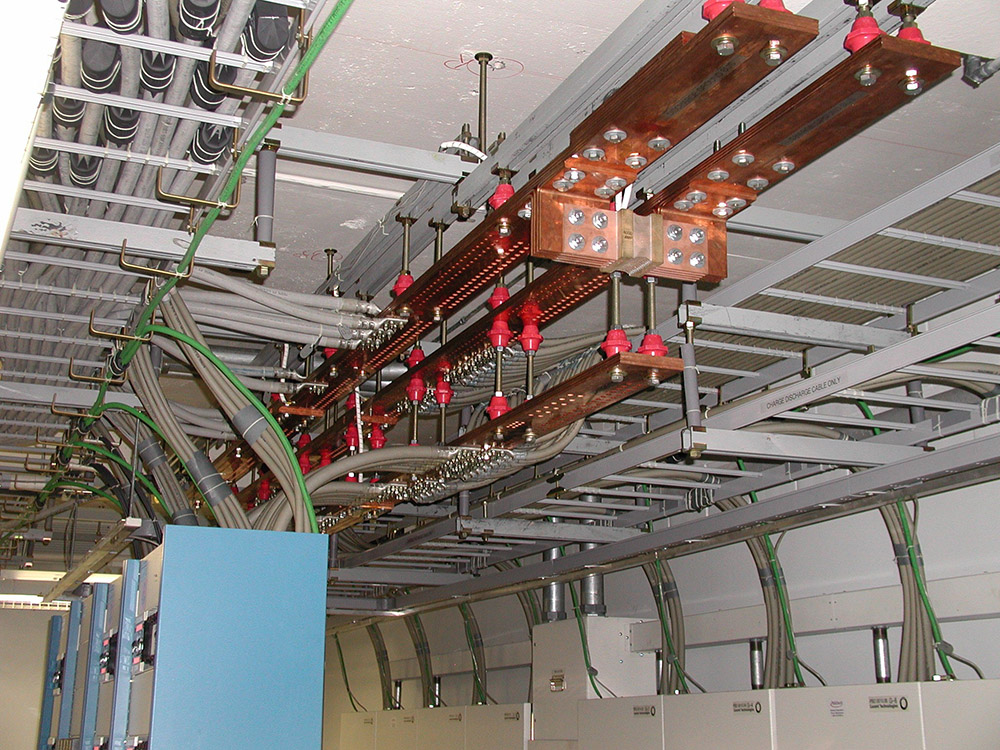

The ampacity of most UL listed equipment is done by heat rise testing and not by square inches of material. The capacity of bus bars is affected by their orientation (flat or edgewise) and their separation from other bus bars. Ensure the Highest Quality Busbar. Consultant Challenged Contractor that. Copper Bus Bar - We Partner with only the Best Copper Suppliers in the U. Southwire is an industry leader in fabricated copper bus bars and copper bus bar systems including a complete line of high current secondary AC and DC custom copper bus bars used for bus ducts, grounding and industrial applications.

The short-circuit strength of the whole system is dependent on the short-circuit strength of the busbar system and the components that are mounted to the system. The need to determine the operating temperature of current carrying copper busbar conductors was identified by a commercial switchboard manufacture contracting company using superseded Australian Standards for their busbar conductor selection in high current switchboards. A bus bar (also spelled busbar , buss bar or busbar ), is a strip or bar of copper, brass or aluminum that conducts electricity within a switchboar distribution boar substation, battery bank or other electrical apparatus.

The NEC doesn’t show the ampacity of bus bars. However, a 1-inch-square copper bus bar has an ampacity of approximately 250A. A 1-inch-square aluminum bus bar has an ampacity of approximately 000A.

WMWA enables companies to fulfill their project requirements with a wide selection of excellent quality aluminum bus bar products. Owning excellent electronic conductivity and tensile strength, HT CCA busbar could greatly reduce the conductive material cost. Bus Bar Design This document describes rule-of-thumb design laws for unconfined bus bars operating at or near dc conditions in open space. At higher frequencies the “skin effect” must be considered. In multiconductor systems (such as magnet coils) the “proximity effect” must be accounted for and the thermodynamics gets tougher.

Quick Bus Bar Size Selector. Use this table as a rough guide to bus bar cross sections for the ampacities shown. Ask your Hussey Copper representative for a copy. Thus selection of suitable cross section can. Bus Bar rating are standard sizes based in iEC and IEEE.

This quantity is related to the resistivity of a material, which is a measure of how large an electric field is needed to produce a given current density. When repairing motors, we often take the lead wire ampacity charts for grante without giving much thought to how they were developed. Who figured out how much current is acceptable for a specific lead wire, and why are there different ratings for different types of insulation? Now go to the ampacity table and look in the 60.

Tapping Busbar Considerations. Ampacity is defined as the maximum current,. It is most often used for electrical suppression in low voltage applications. The primary differences between aluminum and copper bus bar is that aluminum is more cost-effective and lighter weight.

This calculator also provides wire size correction factors for temperature, number of conductors in a raceway, and voltage drop for long wire runs. Table gives a brief review of the sizes of bus bars used for various main bus continuous current ratings in Siemens types GM-SG and GM-SG-AR (up to kV) and GM(up to kV) metal-clad switchgear. Bus bar shape will be affected by termination locations, enclosure constraints, operating environment, and mounted components. When determining overall dimensions for a laminated bus bar , allow for sufficient insulation extension beyond the conductor.

I need help in the following issue: Busbar calculation. Formulas Dimensioning criteria. The ampacity of a busbar (or any other conductor) has to do with the cross sectional area, the conductor material, and the allowable temperature rise.

When compared to a copper bar with the same cross-section there is a significant weight saving, up to less, with an ampacity reduction of about. TPN- ()x80xIf we are going with Copper bus bar than we will use = 40x10sqmm per phase = 40x10x1. Electrical Calculations L.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.