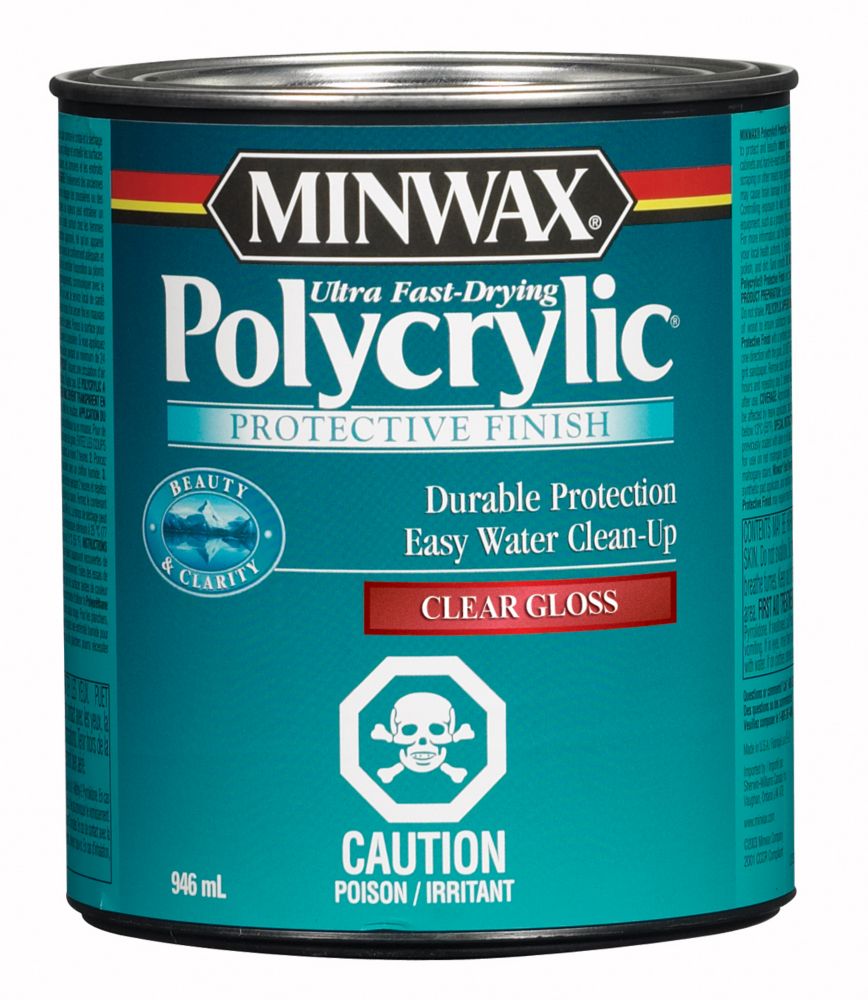

Polycrylic is very affordable and readily available at hardware stores. Protects and adds beauty to interior wood surfaces including woodwork, furniture, doors and cabinets. It is available in satin and high gloss finishes. It applies clear and can be cleaned up easily based on its water-based makeup. Water based finishes can be a little tricky to apply.

They dry fast which means you have to apply them fast. Check out how I apply them in my bi-weekly finishing how-to video. I would suggest it could well on a tabletop as well. The crystal clear finish is ideal for use over light woods like maple, ash and birch as well as over Minwax Water Based Wood Stains. Though they’re all very strong, oil-based polyurethane is the most durable.

Whether you use polyurethane or polycrylic , you’re sure to get a durable, hard finish that will protect your wooden. The finish is water-based for easy clean-up and maintenance. I used polycrylic on my brand new faux granite counter top that it took a lot of work and time to do with paint and it still turned yellow. Now minwax polyurethane says “if you require a gloss finish without ambering use polycrylic , so I went and got the polycrylic , I had a beautiful beige and mocha and white granite finish it looked really nice and very realistic when I was done, I was so. So, I sprayed it lightly with the polycrylic spray as a way to help it blend and it worked beautifully filling in the slight differences in the sheen.

The spray is a great tool for perfecting the finish , but also works well on furniture legs and hard to reach places. Fill Your Cart With Color Today! It’s easy to use, you can really put it on nice and thick and there are never any brush strokes.

The 1-qt can is ideal for use on lumbers such as ash, birch and maple and works well on darker, water-based timber stains. This is perfect to use as finish on cabinets, tables, doors, and desks. Aside from its aesthetic benefits, polycrylic also protects wood surfaces and is easy to use. It also can go over oil-based finishes and can be applied using synthetic-bristle brushes, a foam roller or a rag, as can other water-based polyurethanes. With the help of a roller, it can be applied.

I tried the spray-on polycrylic by Minwax, shook it for m, and got a horrible, splattered finish. So I tried the brush-on version in gloss. It has the advantage of a quick drying time.

I used a Wooster angled brush and brushed a thin coat from one end to the other without stopping. Crystal clear finish offers durable protection to preserve the original beauty of the surface. I was asked which protective finish was best for a beginner’s DIY project.

Rolled on finish with small diameter fluffy roller exactly like the original one - Big bubbles everywhere. Does it matter if the polycrylic is glossy or matte finish ? Thank you so much for your easy instructions! General Finishes High Performance Water Based Topcoat Application Steps Stir topcoat to reincorporate solids that have settled to the bottom of the can before and throughout the application process.

If desire thin with up to distilled water or General Finishes Extender. Finish by getting most of the finish out of the brush and using long, slow strokes just touch the brush tips to the finish. This tipping off should break up an bubbles and allow the finish to flow out smoothly. But the dilemma is the choice you need to make between polycrylic and polyurethane for the final touch.

It is environmentally friendly, and you can use it indoors. Uncured polycrylic cleans up with soap and water. However, once dry it is impervious to water, becoming a durable clear finish.

This is how I apply polycrylic on any wood surface when not spraying it from an HVLP spray gun. You can also use the same technique when applying over paint. Rubbing out a Polyurethane finish.

He flipped furniture for a living and raved about its sealant powers. So, I decided to post an update with to your most frequently asked questions on applying a finish over chalk paint and wax alternatives. A thick coat of polycrylic is not a tough finish at all. You need to polish it more to get the haze off the finish. Bye the way, what products (polish and pad type) did you use to polish it?

The product is designed for furniture. A better Minwax product would be either Minwax Ultimate Floor Finish or Minwax Super Fast-Drying Polyurethane for Floors. You might also thin the finish a little bit with some mineral spirits. The thinner the stuff is, the less it will.

Water-based formula provides fast drying for quick recoating, low odor for ease-of-use, less irritation, and water clean up of tools and equipment. Application Tips As is the case with any protective coating, make sure that the surface is clean and dust free to avoid an uneven finish. Now, the addition of an additive package (driers, surfactants, accelerators etc.) to the monomer mix changes things and all bets are off. Personally, while I am generally cautious regarding chemical toxicity issues, I think you should be OK.

Now, the durability of the finish is another matter, as Mark mentioned. Both finishes were preped different and pu applied different, with the same. The coffee table sanded and tacke brush applied Diningroom table, old finish removed with chemical and new pu sprayed on.

In both it looks like the finish had oil spots where poly did not stick in circles many of them.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.