Plywoo a wood structural panel , is sometimes called the original engineered wood product. Plywood is manufactured from sheets of cross-laminated veneer and bonded under heat and pressure with durable, moisture-resistant adhesives. Wood Structural Panel Installation Best Practice. Wood structural panels can de fl ect and sag under load when installed at their IRC permi tt ed span limits. This can allow cracks in rigid fl oor covering materials such as tile and marble.

Oriented Strand Board is a widely use versatile structural wood panel. Manufactured from waterproof heat-cured adhesives and rectangularly shaped wood strands that are arranged in cross-oriented layers, OSB is an engineered wood panel that shares many of the strength and performance characteristics of plywood. WOOD STRUCTURAL PANEL SHEAR WALLS This part of the Shear Walls section will discuss the components of wood structural shear walls, their correct installation and the effects on seismic performance when they are improperly installed. The components examined will be lumber, sheathing, and fasteners. Panels shall be identified for grade, bond classification and Performance Category by a grade mark or certificate of inspection issued by an approved agency.

Review wood Structural Panel (WSP) mfg standards and specification guidelines. Demonstrate efficient structural design of (WSP’s) as well as methods of reducing floor squeaks through proper sheathing installation. Discuss the role that framing and panel layout can have in the overall efficiency of a wood construction project.

The wood strands are mixed with resins, arranged in layers for design strength and stability and bonded under heat and pressure. Wood Skinned Structural Panel AD LOC 7is a wood skinned structural panel that is thermally broken with wooden studs at 16or 24” on centre, custom sizing available. Not limited to plywoo but applies to all woo-based structural panels in general, regardless of composition.

Manufactured from water resistant, heat-cured adhesives and rectangular shaped wood strands that are arranged in cross-oriented layers, OSB is an engineered wood panel that shares many of the strength and performance characteristics of plywood. Wood -frame structural panel diaphragms. Design of the lateral force resisting system (i.e., shearwalls and diaphragms) must be approached from a system design perspective and is addressed in Chapter 6. A strip of wood structural panel cut from the same material used for the panel facings, used to connect two structural insulated panels. The strip (spline) fits into a groove cut into the vertical edges of the two structural insulated panels to be joined. Major Buyout Hardwood Sale.

Panel Sheathing Structural panels used in the wall tests were manufactured in accordance with the requirements of either U. The tests described in this report also apply to wood structural panels meeting the requirements of U. Product Standard PS (17), which is based on APA PRP-108. In these studies, a 000-cubic-foot chamber was loaded with a sufficient number of test panels to obtain 0. Step – Design the shear walls. The first step in designing for combined shear and uplift is to design the required shear for the structure. ABSTRACT Current American Society for Testing and Materials (ASTM) tests for edgewise, or racking, shear in structural panels lack the capabilities to keep up with the changing wood structural panel industry. To qualify for a given Span Rating under the standards, a panel must meet all of the criteria for that rating.

Examples of wood structural panels are: Composite panels. A mat-formed wood struc-tural panel comprised of thin rectangular wood strands arranged in cross-aligned layers with. AFPA American Wood Council. These values do not apply to Structural I panels. IBC and IRC list the minimum thickness of sheathing depending upon the spacing of the roof framing.

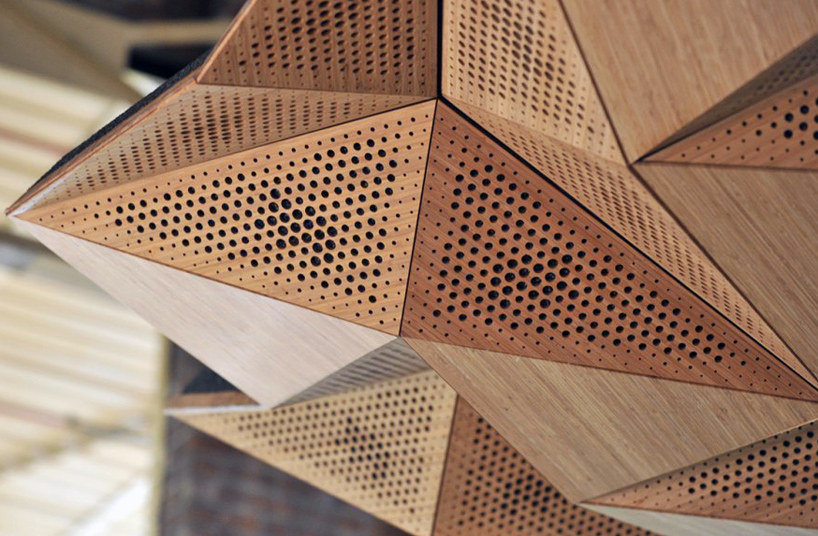

Because the wood in wood structural panels is either cross-laminated or randomly oriente any cut made in a wood structural panel is a cross cut. Always use a cross cut saw when hand- or power-sawing wood structural panels. N’H n’H ceiling elements offer many advantages of modern timber construction and can be used in all areas such as roofing, ceiling, and walls.

Good structural panels are often used with structural components such as trusses to provide the structural decking for the floors and roofs. Familiarity with the terminology used with wood structural panels can help component manufacturers communicate better with architects, engineers, contractors and installers. International Code Council’s Los Angeles office.

This industry-leading product uses a specially-designed polyurethane closed-cell foam that offers several crucial advantages: strength, thermal performance, and a Class I fire resistance rating. Continuous Sheathing Methods include: † CS-WSP: Continuous wood structural panel sheathing † CS-G: Continuous wood structural panel adjacent to garage door. This white paper is intended to explain APA’s position on the panel sizes. The connection from the top of the panel to the framing has also been updated. The new Strong-Wall Wood Shearwalls.

Floor sheathing is a structural component of a building which carries the live loads from above to floor joists below. It is a tongue and groove structural panel that is fastened to the floor structure with nails and glue. Structural Insulated Panels The panel to use if your are making a building with SIPs as the primary structure. SIPs provide exterior sheathing, insulation, and an interior nail base for your choice of interior sheathing.

Tables and of this report. Segmented Shear Wall Design (SSW) is the traditional design method that has been used for many years.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.