Anyway, I am building a shed and I want to use a specific type of Shiplap siding. A router bit with a bearing pilot usually costs a bit more than a comparable bit with simple pilot shaft. Can someone give me idea on how to make shiplap. For large jobs, the cost difference is usually worthwhile since. When installing shiplap siding vertically, bevel cut the upper end of each board so they shed water.

A piloted rabbet bit and a router arc all you need to make them. Roll the board onto its back and repeat. The utility of the shiplap as a precision-Fitted joint?

If you make one shiplap board and aim a laser scanner at it, you will be able to automatically generate a three dimensional model of it which can be programmed into the CNC machine to generate thousands more which are just like it. Personally, I tried both the router and the table saw. Making shiplap siding involves using a router fitted with a rabbet bit. The router and bit are used to cut the notches into each edge of the boards. The top edge of a shiplap board fits into the notched underside of the board above it.

I attached a shiplap fence to the router table with c-clamps after cutting out a hole in the middle of the fence. Ship lap siding has been around for a long time and was used a lot in old tobacco barns. This how-to video shows the process of making ship lap. Re: Thoughts on making your own shiplap ? Buy Industrial Quality Router Bits Free Worldwide Shipping! Fill Your Cart With Color today!

Fortunately, this time you will try to work on a shiplap using a router bit specifically designed for that. In determining a router bit , you must understand that like other machine parts, there are many types of router bits. Router bits are most often used because of the ease of operation is dado bits. Shiplap tools make creating custom boxes out of fiberglass ductboard as simple and as quick as possible.

A moulder may likely do the best job on flooring and shiplap , you can make shiplap and flooring on everything from routers to table saws and even radial arm saws but the trick to precise board width is a moulder or at the least a double spindle shaper. I am not a novice with my router and table, but I am not a master with it either. Ideally it would be nice to find one bit that will make the lap and the v cut in a single pass.

How do i make Ship Lap Interior. If you are wanting to make proper shiplap u need a. Handheld router with rabbeting bit. Unlike saw blades and dado sets, router bits do not leave tiny scoring marks. So, use a router bit if the surface or ends of the rabbets will be visible in your finished project.

Find Raised Panel Router Bits Now! We price match all competitors. Woodworking Machinery Distributor. A shaper would be a better tool if you are going to be making large quantities of siding.

A router could be used with a panel rising bit, then cutting the rabbet on the table saw with a dado will be faster than using a router. Here is the type of bit you’d need. You will want to slow your router way down when using large bits like that.

With the width the same on both sides of your boar you can adjust the reveal between boards when you install the decorative shiplap siding. Pile all the lumber on sawhorses and run one board at a time: up one side - flip - down the other side - move it to the back of the pile - next board. Jig saw or router with a flush trim router bit , or coping saw. Rabbet Joints with a Router. Another option for making shiplap yourself is to use a shiplap router bit set.

Obviously the trim is going to have to be replaced. These bits are the same ones that are in the set above. SHIPLAP : A LITTLE BIT GOES A LONG WAY – Harvard Design. Large router bit sets are a great way to get into the world of routing without breaking the bank Often.

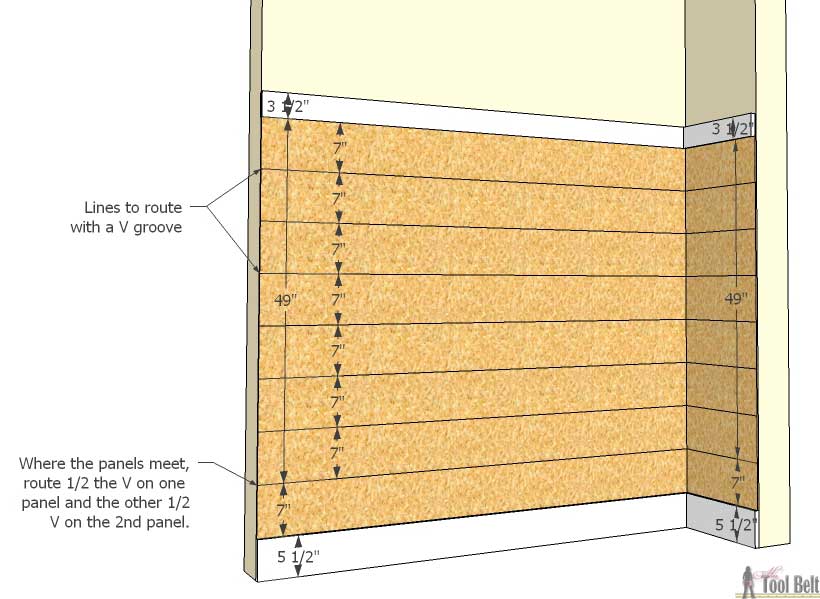

Shiplap , like tongue and groove, has a special rabbet or notch cut on the edges of the board. These rabbets allow the boards, when installed horizontally, to self-space themselves and keep water from getting behind them because they fit so perfectly. You can make your own shiplap wall with plywood! Learn how we saved money by making our plywood shiplap instead of buying the premade shiplap.

It all started when we rearranged furniture in our living room and opened things up a bit.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.