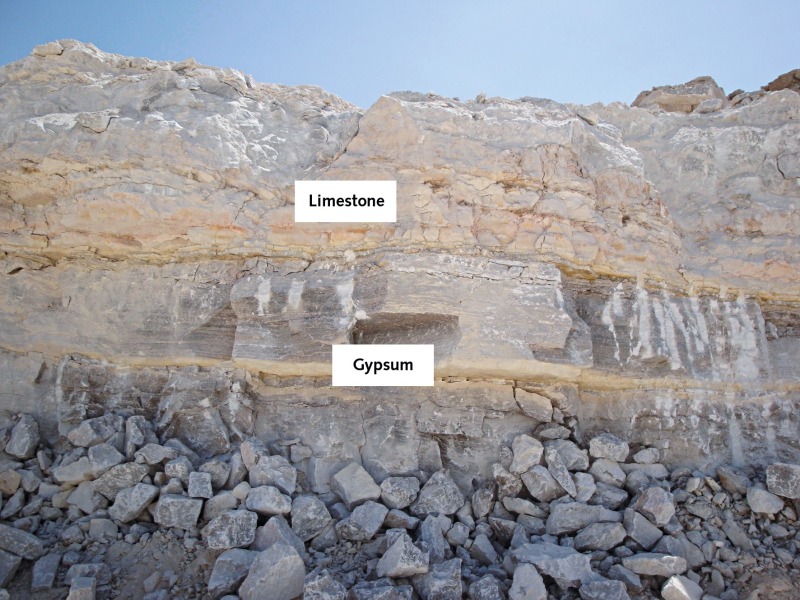

The terms cement and concrete are used interchangeably, although cement is actually an ingredient of concrete. Without gypsum, cement clinker can condense immediately by mixing with water and release heat. The major reason is that C3A in the clinker can dissolve in. Uses of two elementary building materials: gypsum and cement production.

Dissolvine chelates, an efficient retarding agent in cement and gypsum. Rapid setting of Portland cement and gypsum can be a problem. For example, in modern gypsum board mills the proper balance of multiple admixtures is essential for optimal operation. It is mainly used for regulating the setting time of cement and is an indispensable component. Designed for thin sections, its high green strength minimizes breakage during removal from the most intricate molds.

When formed under a template it is slightly on “short side” and has a tendency to tear. The setting expansion is somewhat greater than with A-or B-cements, but higher wet and dry strength is provided. Compare Multiple 5-Star Local Pros.

Because gypsum concrete is a poor conductor of heat, installers often double or triple the amount of tubing in order to improve output. Exceptionally strong gypsum cement designed for stretch-press dies and producing cope-and-drag equipment. Produces high-quality, indoor novelty and statuary castings that require extremely hard surfaces and superior reproduction of fine detail. Super-strength gypsum cement recommended where extreme accuracy and greater surface hardness are require as in duplicator models. During the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding process.

It is used in manufacturing plasterboar cement , and fertilizers. Interior surfaces sometimes receive a final layer of gypsum plaster. There have been recent technological advances in the gypsum cement underlayment market that raise the bar on what you, the customer, should expect from a gypsum cement underlayment product. The high temperature heating furnaces, exposed metals and refractories often experience high temperature oxidation corrosion attack and fail prematurely. Crude gypsum is used as a fluxing agent, fertilizer, filler in paper and textiles, and retarder in portland cement.

About three-fourths of the total production is calcined for use as plaster of paris and as building materials in plaster, Keene’s cement , board products, and tiles and blocks. The business has grown tremendously in the last ten years, and today we are one of the leaders in cement and gypsum trading throughout the entire UAE. Excess amount will make the cement disintegrate, which affects. Because gypsum offered significant advantages over traditional heavy masonry and concrete , the gypsum industry focused on expanding its use in commercial construction.

To meet the demands of high-rise building, the industry developed gypsum board shaft wall systems and movable partitions systems as well as improved fire resistance. Due to having fire-resistant qualities, it has been the material of choice for building structures since ancient times. Now if you compare this weight to Portland based concrete with sand and stone which weights on average 1pounds per cu. Note 1: The setting time is accelerated by the addition of other materials.

Utilization of gypsum as construction material. Plaster ingredients are used in surgical splints, casting moulds and modeling. Be used as a filler and fire retardant in plastic products.

Be used in Portland cement and special cement products for set and expansion control. Be a source of Calcium and Sulphate Sulphur for plant growth. K gypsum floor underlayment is engineered to deliver compressive strengths up to 2psi (2 MPa), also delivering enhanced resistance to surface abrasions and even faster drying time. Low-absorption gypsum cement offers longer set time – ideal for larger molds.

It has the lowest expansion of any rapid setting gypsum cement available. This chapter highlights the usage of gypsum , which has long been recognized as an important and essential component of Portland cement. Now, SCG has become the standard for highest-quality and best-performing of drywall systems and related building materials products for internal wall, external wall and ceiling purposes. SiOSiO and (CaO)and (CaO) 2. Hydro-Stone gypsum cement is one of the hardest and strongest gypsum cements.

It has a heavy, syrupy consistency that is ideal for pouring solid models or patterns. Traditional cement boards like PermaBase are extremely versatile and can be used in a variety of applications. PermaBase is perfect for interior uses such as floors, walls, countertops, or ceilings.

Cement Clinker Chemistry (CaO) 3. It is also a terrific product for exterior walls and soffits for tile or stucco finishes. There are 1gypsum cement mortar suppliers, mainly located in Asia. The top supplying countries are China (Mainland), Hong Kong, and Turkey, which supply , , and of gypsum cement mortar respectively. Gypsum cement mortar products are most popular in Mid East, Southeast Asia, and South Asia.

For more than 1years, SCG has led the Drywall, Fiber cement boar Gypsum board and building materials innovation. Gypsum Concrete systems were used in designs requiring up to two hour fire resistance ratings, wind uplift of UL Class 9 and where strong downward load resistance is desired. Truss tees were used to increase horizontal shear forces for building construction. Gypsum based ceramic tile adhesives are also available. The Gypsum Plaster are commonly used for making Architectural fancies and Decorative Designs on wall and roofs.

Their most important Properties are: They have great resistance to fire. Gypsum , gypsum plank, gypsum plank decking, gypsum decking, sub-purlins, cross-tees, gypsum deck plank, gypsum deck, grout, deck system Description This section specifies gypsum plank systems for fire rated interstitial decks and roof decks. Introduction Portland cement gets its strength from chemical reactions between the cement and water. The process is known as hydration.

This is a complex process that is best understood by first understanding the chemical composition of cement.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.