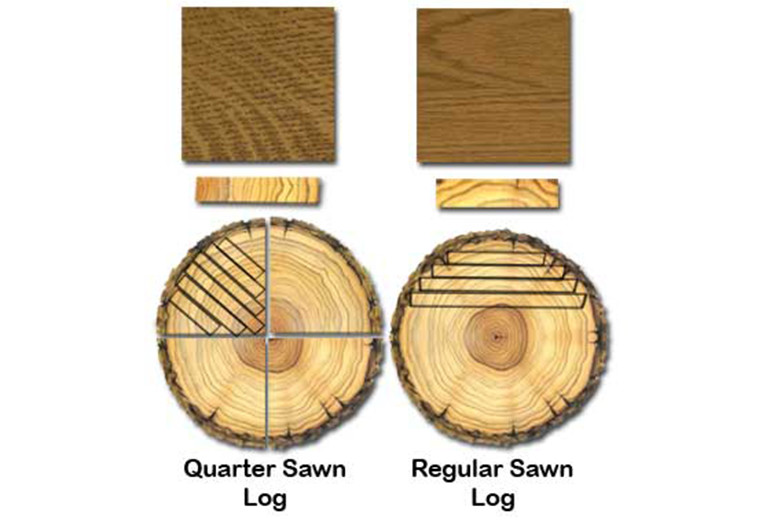

There is widespread confusion between the terms quartersawn and riftsawn with both words defined with opposite meanings and as synonyms. More physical labor and time are required to make a piece of lumber, or flooring plank quarter sawn. When cutting this lumber at the sawmill, each log is sawed at a radial angle into four quarters, hence the name. Quarter sawn wood is more dimensionally stable than plain sawn lumber.

A WoodWorkers Guild of America (WWGOA) original video. The choice of quartering method is usually based upon the size of the log and the sawing equipment used. It is seldom profitable to quarter saw logs under inches in diameter because of excessive waste. Often used for cabinetry, flooring, high-end custom crafts and furniture, it is the traditional wood used in making mission style furniture. Quartersawn lumber comes at a premium due to the labor it takes to mill each plank.

The resulting lumber is called quartersawn ( quarter - sawn ), quartered , and radially- sawn. To mill quarter sawn woo each log is sawed at a radial angle into four quarters. Then each quarter is plain sawn.

This method of quarter sawing does leave some waste, but much less than rift sawn lumber. I have a customer who wants quarter sawn sycamore. Does every board have to be true quartered for the figure to show, or will the traditional methods of quarter sawing produce good ? As I understan sycamore, unless quarter sawn , will warp excessively. After the logs are debarked and quarter sawn , they are kiln dried with a slower drying process than plain sawn lumber.

It is because of the higher value log and additional time in the mill that quarter sawn lumber costs more than plain sawn. Ever wonder why quarter - sawn lumber is more expensive than flat- sawn lumber? The answer lies in the milling process. Author and furniture maker Mario Rodriguez gets to the bottom of this question during a visit to the mini mill of Dave and Carol Spacht in Worcester, Penn.

QUARTER SAWN More expensive than plain sawn material. With perfectly sawn quarter sawn lumber you are going to have to accept the waste problem, but it is worth it. I do a bit of quarter sawing with high-grade white oak logs on a Wood-Mizer (hydraulic) bandsaw. Quarter (Grade) Sawing The alternative is quarter - sawn timber, where the grain lines are parallel with the narrow side of the board. This type of timber is beneficial in furniture making, as it is very stable and dries more evenly.

OWW I drew lines on one of your quarters, showing how I helped quarter saw red oak, after first quartering the log as you showed. We put a table on the bunks and clamped it, and it had a fence with a lip on one side. Rift Sawing is cutting radially perpendicular to the growth rings of the tree.

In quartersawn woo only the center board of the quarter -log is cut with the growth rings truly perpendicular to the surface of the board. Quarter Sawing is cutting radially into four quarters. Rift- sawing is a woodworking process that aims to produce lumber that is less vulnerable to distortion than flat sawn lumber. The other method is cutting the log above the pith at the point where the boards will be changing from quarter to rift, then saw boards on down until again the boards are changing from quarter to rift.

This gives you very nice, perfect quarter sawn boards that will need the pith area cut away, which means splitting the boards. CUTTING BOARDS FROM A LOG. The methods of cutting wood are determined by the intended use, appearance, and stability of the wood.

There are three cutting methods, of which the first two are the most common. Plane Sawn This is the simplest method. The log is squared and sawed lengthwise.

The 2nd row 2nd column is quarter sawing. It takes time to quarter saw and most sawyers don’t like doing it for cheap if they’re cutting a lot of lumber because of the time issue. The red part you highlighted does not exist in quarter sawing. You actually highlighted different pieces with your red box.

Your blue box highlights boards. I can either complete the sawing on the resaw (best method) or set the cants aside and saw them into lumber on the Woodmizer a little later. If the cants stay straight, the sawmill will do just fine, but if they ben the resaw will do a better job. Now, I cut the best and widest quarter sawn boards - two at a time. Riftsawn this is the most work intensive and has the most waste from the log.

True quartersawn lumber is produced when the growth rings of the log are sawn as close to perpendicular as possible. Each board produced using this method of sawing possesses grain patterns that are both unique and beautiful. This particular method of sawing produces a nice straight grain appearance on the face of the board. QSF Manufactures the Finest Quality Wood Flooring Available Anywhere.

Allegheny White Oak Live Sawn is the result of straight cutting the log from the outside diameter through the heartwood.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.