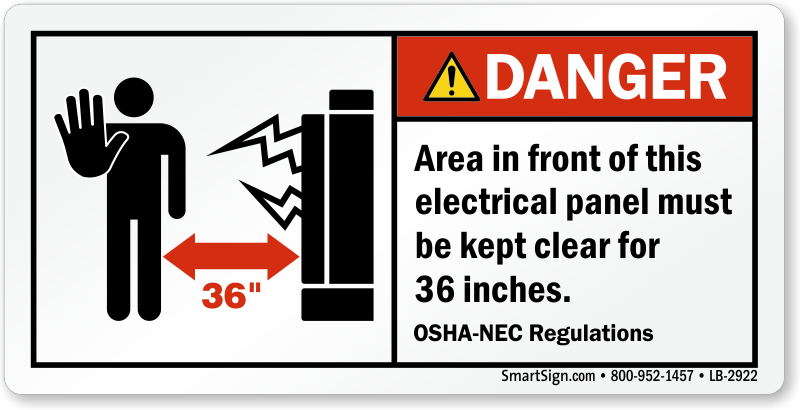

Enclosure for electrical installations. To ensure that an electrical panel can be accessed at all times – during inspection, maintenance or emergency – OSHA has determined that the working space in front of the equipment must be at least 30-inches wide (or the width of the equipment). Maintaining clearances around electric panels.

Insufficient clearance around electrical panels is one of the many electrical hazards that can endanger worker safety. Obstructed access to panelboards can prevent personnel from shutting down the source of power in the event of an accident. Blocking electrical panels is a violation of regulations.

A signal or flag person must guide cranes, cherry pickers, high lifts, and other equipment in transit near exposed energized lines or parts at all times. The working width around the panel must be at least inches. Most stock orders ship same day and custom orders in as little as 1-days.

So, therein lies my dilemma. Electrical Panel Safety Signs Ship Fast. Our safety guy says that OSHA says that electrical panels must be kept clear for 3 or so he thinks. Fortunately, posting signs about Eletrical Panel hazards reminds everyone in your facility follow established safety procedures. OSHA and NEC regulations mandate that guarded locations with live exposed parts should be kept clear at all times.

Keep the electrical panel area clear by installing this high visibility OSHA safety sign. However, in many new and existing installations, proper clearance may not be possible. Therefore, the designer, contractor and the authority having jurisdiction should take that into consideration when verifying if less working space around electrical equipment, as well as clearances , is allowed.

Question: I own a Pizza parlor. There is an electrical panel in our back room near storage racks. The panel is about chest to head high. Some people have told me I must keep the area around the panel clear from the panel to the floor.

Others say just around the panel so it opens easily with no obstructions. OSHA clearance requirements say that employees must have at least feet, inches headroom above work spaces above switchboards, panel boards, motor control centers and service equipment. If you are adding a sub- panel , adding circuits, or rearranging circuit breakers in your panel , be sure to talk to an electrician to make sure the work gets done right — for your safety and so you’ll meet electrical inspection requirements.

Where should a breaker panel be located? Aisle Marking Tape – creativesafetysupply. This clearance is measured for the live electrical parts or front of the electrical panel. A minimum of inches of width is also required in front of the electrical panel.

OSHA and the NEC both mandate a minimum clearance of inches on panels of less than 6volts and less that 60symetrical fault amps. Panels operating at higher voltages or electrical. This feature is not available right now. What are the clearance requirements around the surfaces of Ventilated Transformers.

Various NEC codes and OSHA regulations require that areas around electrical panels be kept clear at all times. Typically feet deep, inches wide, floor to ceiling). Exposed live parts on both sides Up to 1V 0. Breaking into the world of electrical installations is next to impossible. Our in house safety person says that the expectation of clearance of a local disconnect is the same as the electrical panel that feeds it. Per the NEC there is clearance needed by a circuit panel.

The minimum electrical clearance is the minimum distance between electrical conductors with different potentials (voltage). Clearance around an electrical panel ? If you need distance in Feet just convert meter in to feet…1Meter=3. Train employees that are face exposure to live wires. Make sure everyone else has clear working space and will be guarded from electrical exposure.

Department of Energy AREA SAFT Washington, D. IAEI, as the keystone of the electrical industry, is a membership driven, non-profit association promoting electrical safety throughout the industry by providing premier education, certification of inspectors, advocacy, partnerships and expert leadership in electrical codes and standards development. Use a electrical panel maintain feet clearance all material at all times sign. Give safety a hand - with a sign. Make safety and compliance the building blocks of your success. Clear sign gets the message across.

Also clearances from water supply, drain, and sumps must be considered. To enhance safety , post the location of the electrical panel on the equipment it services. Never obstruct electrical panels and disconnect switches.

These should be clearly labeled to indicate what equipment or power source they control. A minimum 3-foot clearance must be maintained around electrical panels at all times to permit ready and. Not less than 6mm wide and 2. I am adding a sub- panel to an existing panel.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.