The plywood thickness is not the same for every board. The weight of a plywood sheet will proportionally increase with increasing in width, length and thickness. And the whole 4’ x 8’ sheet will be approximately lb. While the length and width of a sheet are pretty straightforwar the thickness dimensions are anything but.

Such charts also give weights for plywood made from different materials and grades of material. To find the weight of a piece of plywood , builders use a plywood weight chart. For instance, if a builder needs to know the weight of a standard 4-foot by 8-foot sheet of plywood , he can measure its thickness and consult the plywood weight chart. Because the actual thickness may vary measuring the plywood is the only accurate way to determine its thickness. Softwood Lumber Dimensions – 2x Nominal.

X length in inches x thickness in inches. Thickness Conversion Table. These extra long lengths are generally for use in homes with extra high ceilings.

Note: The convention to indicate grain direction is used whereby the first dimension shown is the direction of the surface veneer grain. In North America, hardwood lumber is usually specified using the quarter system, where a board is identified by its thickness in quarters of an inch. What do these lumber fractions mean? In short, these fractions are the names for the thickness of hardwood lumber. The thickness is expressed as a fraction, and goes in increments of quarters of an inch.

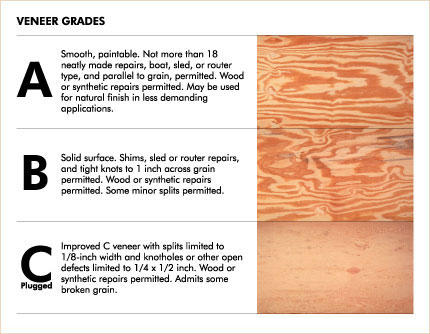

For joist spacing of more than inches up to 19. A typical plywood grade would be A-1. This means that the plywood would have an “A” grade face with a “1” back. A-and B-plywood grades are typically the grades most often used in ½” and thicker panels for cabinet work.

The most common grade used in ¼” panels is A-4. This number is known as a span rating. When installing a plywood subfloor on top of the slab at grade, the. TECHNICAL INFORMATION SHEET. Metric sizes are also available.

Shear value through its thickness is twice as that of plywood and hence is the choice for. This flexible product can help with roofing, flooring and hoardings. Plywood Design and Application Guide.

The tendency for hardwood plywood panels to vary in thickness from their stated dimension can be frustrating. Pressure-treated plywood , which is saturated with chemicals to ward off mol mildew, and insects, can survive outside for decades without paint or a protective finish. In most home centers, pressure-treated lumber is located in its own aisle, and has a distinctive green cast to its color.

Commercial Lumber Sizes Chart Table. With well over a century of experience, Boral plywood is produced at the company’s dedicated mill in Ipswich, Queensland. Laminated Strand Lumber Laminated Veneer Lumber Fire Safety Manufacture Quality Control Sizes Available.

Though the metric system has largely been adopted in India, the prevalent practice in the plywood market is still to manufacture and sell the boards based on cost per sq. Standard plywood sizes and thickness in India. Our lumber seems to thin at times, especially quartersawn.

A: Based on your company’s products, I think you are concernedabout hardwoods. All plywood runs the risk of warping, and the most common type of warp in plywood is bowing. Baltic birch is not immune, it’s still a wood product. LUMBER TABLES: To assist you in your new profession, we have included these handy tables.

Here you will find conversion tables for Board Foot Measure, Conversion from Board Foot to Lineal Feet, product classification and Dimensional Data for Nominal and Dressed Lumber. Major Buyout Hardwood Sale. Actual plywood weight is slightly less, as the specification is for pre-sanded sheets. The organisation offers a bunch of technical informations and educative content. To compare and visualize the difference in weight and thickness , look at the following tables below.

A final mark to check is the thickness of the plywood. In reality, these measurements are not a true measurement of the lumber thickness or width. The true measurement of a 2xis actually about 1. When the board is first rough sawn from the log, it is a true 2x but the drying process and planning of the board reduce it to the finished 1.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.