From superinsulation and daylighting to lightweight plastics replacements, catalysts, and batteries, aerogels offer a wide range of unique materials properties that make possible next generation energy-efficiency and scientific applications. Typically, silica aerogels and non-silica aerogels range from about 0. Aerogel Prices to Drop by Percent? The aerogel insulation felt made of the same has a thermal conductivity of 0. Current carbon aerogel thermal insulation (see link below) is made via pyrolysis (combustion) so is usually fragile and chemically reactive, limiting it to specialised applications (most vacuum-related).

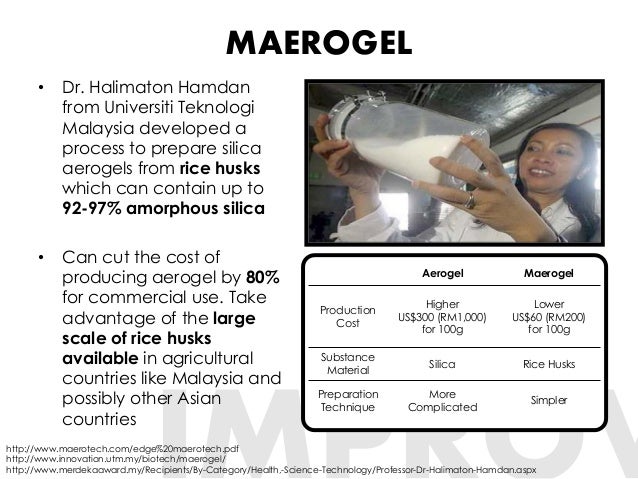

The main problem with using aerogels for home insulation is the variety of low- cost solutions already in the market. Silica composite aerogels - cost analysis: 4. Research into opacifying composite silica aerogel : 4. Because of costs , aerogel manufacturers have focused on high-end industrial applications, such as insulating oil and gas pipelines and even the Mars Rover spacecraft. Keywords: insulation, silica aerogel , raw materials. A couple products are now available on the market, although their use is still constrained because of the relatively high cost of the material. LTD is an innovative enterprise integrating R manufacturing and technical services, focus on electrolytic aluminum equipment, aerogel insulation material,Insulation board main products etc.

For relatively small quantities of aerogel the cost is about $1. Other benefits include long-term water resistance and the ability to wick water away from the pipes, reducing pipe corrosion. That is unlikely to occur, however, until aerogel products achieve cost competitiveness with conventional products.

Our innovative, proprietary process successfully produces high quality material while effectively bypassing the high costs associated with traditional aerogel production methods for safe, continuous manufacture of this versatile and high-performing material. Fill Your Cart With Color Today! Supercritical fluids exhibit much lower surface tension both at the interface to liquids and to the interface at gases. It is this property that allows for the aerogel to be dried without destruction. Silicon manufacturers, homebuilding materials manufacturers and space agencies have all put aerogel to use.

Its popularity has only been hindered by cost , though there is an increasingly successful push to create aerogels that are cost -efficient. In this section of the paper, we compare the current cost of wall retrofit projects using aerogel and conventional insulation approaches. To estimate the cost , different aerogel —both configurations interior and exterior —installationsare considered. Super-insulating glazing and aerogel blankets are becoming more available in the insulation market. However, their current high economic cost means that they are only used where limited space is available and where the use of vacuum insulation panels is not possible due to their drawbacks.

Plus, a full sheet of gel is only maybe ten bucks at most, so I think the cost would be hard to justify. While that is an extreme case, it. Although aerogels are lightweight and provide excellent sound and thermal insulation, their high manufacturing costs and poor mechanical properties have meant that they have only been used in niche applications, such as for insulation in NASA’s Mars rovers. The development of aerogel gold is approaching. In the field of new materials, aerogels have become hot words in the past two years.

The research institutes have been constantly developing new trends and new applications. Commercialization of aerogels has been slow due to several factors including cost and manufacturability issues. The technology itself is well enough developed as a result of extensive work over the past decade by an international community of researchers. However, the high manufacturing cost , the poor mechanical strength of aerogels , and requirement of extensive RD are expected to restrain market growth during the forecast period.

They can made from practically any material, although the most common form is silica aerogel which can be produced as granules or in solid (monolithic) tiles. Commercial products for the building sector include: Cavity insulation. Spaceloft aerogel home insulation supplier in UK, Ireland areas.

Buy aerogel from Enviroform Solutions. Reduce costs and heat loss. These lightweight polycarbonate panel skylights are an excellent value and can substantially reduce energy costs and provide a great return on investment. Energy Efficient Sustainable Construction AEROGELS - Superinsulating Building.

I wonder how much does 1kg of aerogel cost ? Probably a crapload of money, since aerogel weighs next to nothing and liter costs $000. At the moment, it makes good financial sense to incorporate it as part of a comprehensive insulation program. My current favorite is a combination of these aerogel thermal breaks with a high R value vapor barrier closed cell spray foam, and the Knauf ecobatts. But since aerogels are more plastic than fiberglass or foam, permeable to water vapor, and flameproof, the extra cost may well be worth the investment when insulating masonry, shingles, or curved.

Buying quality doesn’t cost , it pays;. It is the type of aerogel most frequently seen in photographs and what people generally refer to when using the word “ aerogel ” without an adjective in front (although there are many other types of aerogel ). Wernery calculates that using the bricks would add $5for every three-square feet of wall. But Koebel and Wernery expect aerogel costs to fall dramatically as they and others come up with lower- cost production methods. Jean Thilmany is an independent writer.

PU foam is just very good. The density is the biggest factor since the cell walls of the foam conduct heat more than the air in the cell. Separex brings aerogels manufacturing breakthrough to EU’s BIO workshop. Separex SCF drying technology can revolutionize the cost effectiveness of aerogels.

Editor’s Note: This is an adaptation of the silica aerogel procedure from the Lawrence Berkeley National Laboratory site about aerogels , which for a long time was the only procedure for making aerogels publicly available. That procedure, we’re sorry to say, does not work. Quartzene is a substantially improved and considerably more cost -effective version of the super material aerogel.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.