What is continuous insulation ? Continuous insulation , also known as CI, is defined by ASHRAE 90. WSP sheathing) to result in walls that are structurally and thermally efficient, durable, and code compliant. Polyisocyanurate (polyiso) insulation is a thermoset, closed-cell, rigid foam plastic insulation manufactured in board form. Via a continuous lamination process, liquid raw materials that expand and become light (yet strong) are applied between engineered facing materials.

Insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. Fortunately, there has been a tremendous amount of experimentation and development of new materials and methods for installing continuous insulationg on buildings. It is installed on the interior, exterior, or is integral to any opaque surface of the building envelope.

High R , radiant and vapor barrier. ROCKWOOL is at the forefront of developing wall systems that meet this call for higher energy efficiency, sustainability, durability and better overall performance in exterior wall assemblies. Rigid insulation sheathing is made of a rigid plastic foam that is typically sold in 4x8- or 4x10-foot boards.

The perfect continuous insulation system that dramatically reduces the cost to heat and cool a building, while meeting ASHRAE 90. It assist in LEED certification and utilizes green building technology, making it environmentally friendly too! Engineered as a continuous insulation solution, SMARTci TM provides best practice for buildings with a continuous insulation system. Patented GREENGirt TM provides a thermal break and mounting platform for cladding applications.

It is an open design that works with almost any substrate, insulation and cladding. Contact continuousinsulation. InSoFast is a one step solution to the complex multiple layers that wall assemblies require. The InSoFast panel provides continuous insulation , vapor barrier, framing, and electrical raceways in one step increasing labor production.

Do the job once and do it right. These materials can be fixed to either the inside or outside of the exterior walls which has the advantage of being a continuous sheet of insulation rather than needing to have breaks for studs or other wall fittings. The topic of continuous insulation is relevant for all types of construction but has been of recent interest within the context of commercial construction. During the past years, the building sector has seen a significant shift around the use of continuous insulation (CI).

Evolving from what was once a rare practice or perceived as an advanced green-building, high-efficiency option to today where CI is now a standard method and materials practice across most climatic regions. Framed wall construction, whether using wood studs or metal studs, has an inherent weakness from a thermal efficiency point of view. Simply put, the framing allows more heat to flow through it than insulation does. InSoFast panels offers an engineered system of continuous insulation perfectly suited for basement insulation.

InSoFast panels remove the complexity of the project by providing a single step, a one trip to the wall finishing. Download our technical guide for finding the right continuous insulation and air sealing solutions that meet energy code requirements. Cold Storage Building Solutions In a low-temperature building, designing for thermal and moisture control is crucial to your long-term performance and energy savings. Prongs enable pre-spotting into insulation (for fast on-the-wall fastener assembly).

RainBarrier products are non-combustible and compatible with common wall ties and air barrier systems. For those who want to stay with the tried and proven method of framed construction, the answer is in providing continuous insulation (CI) that is not interrupted by the framing. By insulating the entire exterior wall span – not just the space between wall studs –thermal bridging is minimized and energy efficiency maximized.

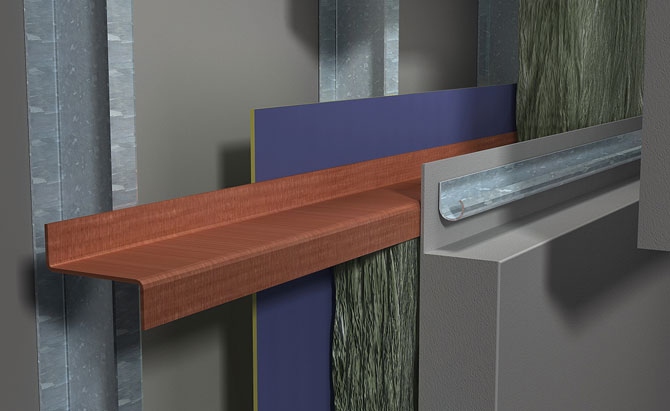

This push for continuous insulation in exterior wall assemblies is also reflected in green building standards and the desires of building owners to reduce energy costs. The response by many architects has often been to use rigid foam board insulation located over the exterior structural face and behind exterior claddings. Rigid foam plastic sheathing materials are commonly used for continuous insulation because of their relatively high R-value per inch and low cost to meet or exceed energy code. R-value should be much closer to the effective R-value of the. This has been proven to increase energy performance by as much as double or more, simply by using the SNS Thermal Spacer to minimize the impact of Thermal Bridging ( U-Value Chart ). The challenge lies in how to design and construct the juncture of materials incorporating the varying thicknesses of insulation and different building finishes.

Done correctly, CI greatly improves a building’s efficiency and comfort. Not everyone is gung-ho about CI, however, so we’ll address some common concerns. The R-TEC exterior cladding attachment system is designed for continuous insulation applications.

The bracket and screw design allow for the use of all types of exterior insulation – from mineral wool to low or high density foam. Provides continuous insulation. Like other building materials, so too does the cost of continuous insulation for commercial buildings have an impact on the overall construction budget. When considering a continuous insulation product for commercial buildings, a common choice is XPS rigid foam board. As the name implies, continuous insulation is the requirement that no gaps or flaws exist in a buildings’ protection.

Polyiso continuous insulation can eliminate thermal bridging at the studs. Higher R-values than the same thickness of XPS, EPS, and mineral fiber, polyiso R-value increases exponentially with thickness. In some areas, the roll batt is covered with a polyethylene vapor barrier , as was simulated in the hygrothermal analysis.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.