Milling rift sawn lumber takes more time and labor. It also has unique benefits over quarter and plain sawn lumber. Furniture makers depend on this cut of wood for the vertical grain that is shown from all sides.

This produces narrow boards and there is a lot of waste between cuts. Sawyers are less likely to make this sort of cut. Similar to quarter sawn lumber , rift sawn lumber is also referred to as radial grain. The woods sapwood is nearly white to light brown and not always sharply demarcated from the heartwood. Drawing a rift sawing diagram on the end of a log would resemble the spokes on a wheel.

If rings are intercepting a plane between and degrees, you get a straight grain, that is a prime example of rift sawn. The other type, quarter sawn , when the grain is pretty much vertical. It is widely used in paneling and architectural millwork, especially in modern, contemporary settings.

Reclaimed wood is a great way to do that! Quarter-Sawn Lumber Quarter-Sawn Oak Hardwood. Only a lot of the wood in between these cuts unfortunately go to waste, making this choice of cut the most expensive of the three.

White oak has a finer texture than Red Oak. Heartwood is decay resistant and suitable for exterior uses. Good turning and steam bending qualities. Thank you for stopping by our website and store.

We are a farm-based business that specializes in milling and kiln drying quartersawn oak and sycamore. Its distinctive straight graining and pronounced ray flecking is prized by cabinetmakers, especially in the Mission and Arts and Crafts style. Hand-Pick Exotic Wood Boards: What you see is what you get! It is ideal for custom furniture makers to use for table, chairs, and other furniture legs that benefit from having all exposed sides with the same linear appearance.

Though it is the most expensive cut of lumber and yields less wood than other cuts, rift-sawn wood is the most stable type of lumber available. Rift-sawn wood is cut along the radius of the log, or at right angles to the tree’s rings. When flooring companies refer to quarter sawn wood , they are usually referring to a specialty wood flooring cut that is a combination of quarter and rift sawn. The straight grain of quarter and rift sawn wood is very consistent, making it desirable among furniture makers.

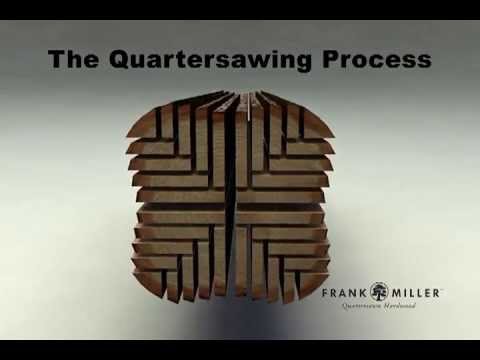

It is the best option for the radiant heated floors and critical applications. When sawing with the rift sawing method the wood logs are cut perpendicular to the tree rings. The resulting lumber is called quartersawn ( quarter-sawn ), quartered , and radially- sawn. There is widespread confusion between the terms quartersawn and riftsawn with both words defined with opposite meanings and as synonyms. Each and every board that was sawn like that would have the growth rings at degrees, which is my definition of quartersawn wood.

Rift Sawn Hard Maple Wood Blanks. The Hardwood Lumber Company manufactures high quality wood stair treads and risers at affordable prices. Our stair treads are milled with new state of the art equipment.

We can make the stair treads with a left or right hand return. The sapwood of red oak is white to light brown and the heartwood is a pinkish reddish brown. Red oak is similar in general appearance to white oak, but with a slightly less pronounced figure due to the smaller rays. This reputation developed from relationships with the renowned Stickley Furniture Company and also the Japanese furniture market.

One of the main costs of lumber drying is time. We are constantly evaluating the drying of lumber based upon how much revenue per day a dry kiln facility can make. The specification is meant for the oaks which have prominent medullary rays. This type of sawing is a technique of cutting boards from logs vertically so the annual rings are nearly degrees to the face. However, it also produces the most waste, which will cost more per board foot than either quarter sawn and plain sawn lumber.

Improve the look of your cabinetry and home furniture using high quality quartered rift black cherry wood veneer available at Oakwood Veneer Company. Instead of being cut to produce plain sawn , quarter sawn , or rift sawn wood , the log is cut straight through with each cut parallel to the last. During the manufacturing process, the lumber is sawn at an angle perpendicular to its annular rings. The close even texture and beauty of Cherry have made it synonymous with fine furniture since colonial times.

Once you have chosen the best wood for your project, shop for the best Cutting Tools. Leo brought pictures and examples of what the finished furniture look and design was. This showed all the reasons why the specs were the way they were, and they could manufacture the lumber with the end product in mind. Each board is cut along a radius of the original log, so that the saw cuts at right angles to the tree’s growth ring. American Black Walnut Veneer has been a standard in furniture and panel manufacturing as well as the standard for gun stocks for many years.

White Oak flooring is a special area of focus for us.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.