For the Love of Painted Woo FJ Pine is the Economical Choice. Uses include fascia, corner boards, trim base molding, furniture parts, shelving, and cabinets. There are no knots to bleed through your final top coat of paint, making it a great product for painting. The finger jointed pine is very convenient for work, for cutting and processing, and respond well to a variety of different adhesives that allow creating a variety of finger or wooden profiles connections to various customize setting.

The carpenters did a nice job of putting it all together, flashing, wrb, glued mitered corners (that didnt open up, nice and tight) and it still failed. This engineered moulding is made by fitting smaller pieces together to create one long board. Poplar is a favored material by design professionals. The crisp grain lines and rich wood tones accept paint and stain, making it a. When carpenters plan to stain interior trim, their first choice is solid wood.

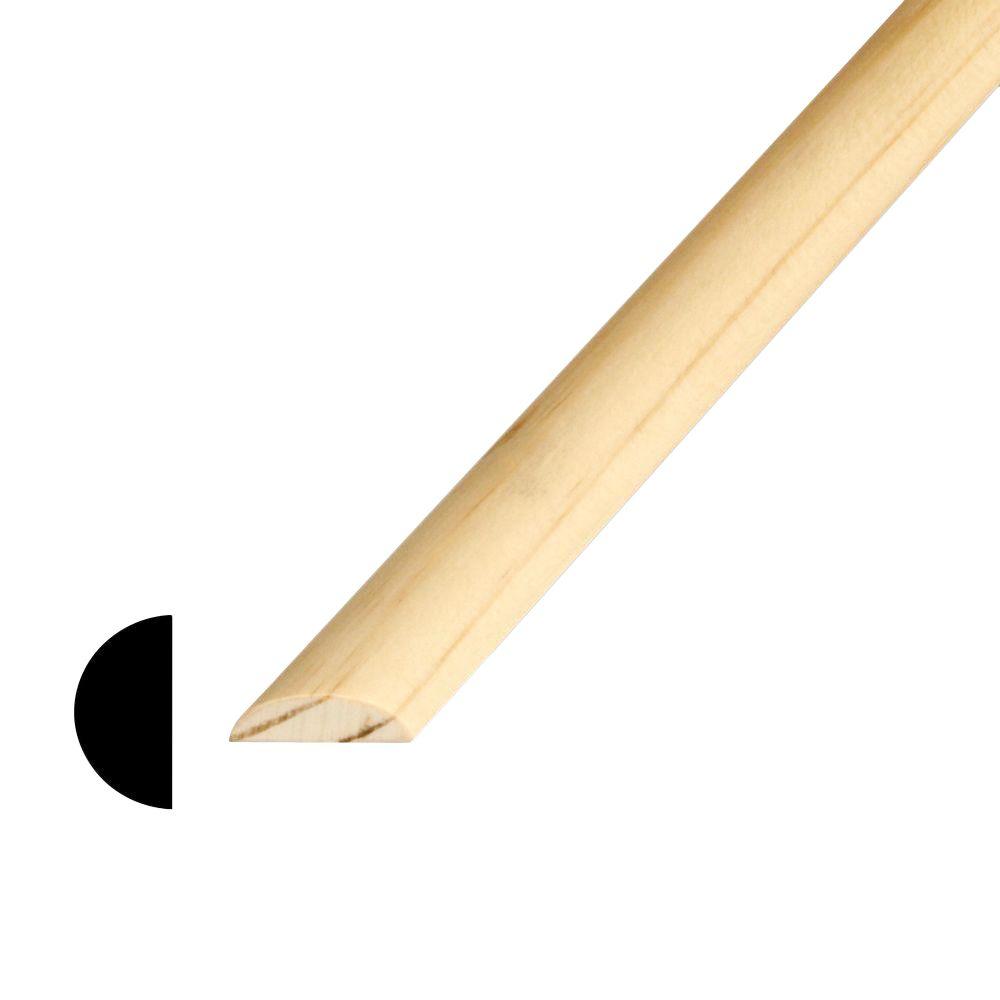

Typically installed where the wall and ceiling intersect, crown moulding is often used to add distinctive style and dimension to a room. Finger Joint moulding looks best when painted. Transition moldings are a necessity for every flooring project. Whether you are transitioning between two rooms, or between two different types of flooring, the coordinating molding provides a smooth transition and a professional look to your project! All baseboards are sold by the linear foot in 8. Design Pine utilises finger joint technology to create long, straight and defect free boards for every application.

Design Pine producers only use exterior grade adhesive in every joint which creates a product with maximum strength and reliability. A finger joint is a joint where the lines resemble interlocking fingers. MDF takes paint very well.

Baseboards are used to transition between a hardwood floor and a wall. Each piece of moulding is ready for paint once prepping is complete. Radiata Pine is a very dimensionally stable pine.

It has a tight, uniform grain, and small limited knots making it great for appearance applications. It is also an abundant species in Chile, and highly sustainable. With existing limitations, the finger joints described are the best that can be produced.

Between- joint variability Is seen as a major production problem. Depending on the type of finger -joined lumber being manufacture edge and flat bending tests and tension tests are performed on each piece to ensure the joint can meet the design value for the lumber. There are two categories of finger -joined lumber depending on the intended end use.

Eastern White Pine finger joint boards in the northeastern United States. Ever stained a piece of finger jointed pine base or casing? Ever tried to caulk a miter on oak or cherry casing?

Different methods for different materials. Still the jobs should have tight miters and joints. I have been asked this questions so many times. Here is the quick run down of FJP. FREE Shipping on eligible orders.

The boards and jamb are available in a Gesso coat prime or raw. The mill that produces both the boards and the jambs is FSC and ISO Certified. There is a difference between it and normal PFJ. IIRC the exterior stuff is treated with something to resist rot and insects. This simple ogee picture rail is truly a classic.

The jointed pine is composed of pieces of pine glued end to end or side by side (laminated). This product is very popular when looking for a very stable pine because the risk of warping is almost none when using this type of product. S4S – surfaced (smooth) four sides. For exterior applications we recommend WindsorOne Protected primed boards (above).

Click here to view our selection of WindsorOne primed mouldings. WOODWORKS AND MOULDINGS FINGER JOINTED PINE. Woodwork and clear pine mouldings can be usually painted since the joints between the planks of wood are apparent.

Finger-jointed pine is a common product used on many upper-end and midrange projects where cost is a concern. The intent of finger -jointing is to eliminate knots in the wood and to yield a straighter board for less money than clear stock. Pine Timber’s technical information Pine was chosen as a plantation species due to its robustness, excellent growth and versatility of its timber. Pine is generally sold in dressed rather than sawn form and is widely available.

Many finger joint boards come from overseas, but we use locally grown and harvested wood and manufacture our boards from start to finish right in Cobleskill, NY. If you see a piece of wood where one grain ends and another grain picks up again, this is the tell-tale sign of finger - jointed wood. It is pre-primed for your convenience with two coats of high quality factory applied primer. Claycoat mouldings are primed with a smooth plaster-like coating.

Other items are primed with a lighter lacquer based primer.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.