In addition to our punched tin early American lighting and wooden chandeliers , we also have a wonderful selection of country home accessories and furniture. In colonial times, punched tin panels were used on pie safes and cupboards to keep the air flowing in to cool fresh baked breads, pastries and desserts while keeping the bugs away from the delicious food. Diamond Cabinet Panel in Blackened Tin $ 22.

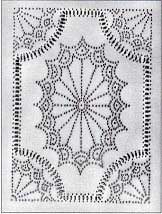

Give your cabinets a primitive country look by replacing the panels with these punched tin panels ! Regular Star Panel in Blackened Tin $ 22. Available: 1Quick View. Punched tin panels will add a country and primitive look to any home decor! Punched Tin Panels for a wide variety of uses, limited only by your imagination! As the focal point in any room, consider an ornate headboar or a striking wall decor made with punched tin panels.

Lay the tin panel on top of the cardboard. Punch each hole with the same pressure for holes of uniform size. Using an awl and hammer, punch a hole in each dot on your tin -punch pattern. Determine the size of the plywood portion of the faux panel based on the dimensions of your cabinet side. We left a 4-inch margin around the sides and top of the cabinet.

Designs depicting sheaves of wheat, flowers or other ornamental patterns were stamped into the panels. Cut the panel to size and sand smooth. Use our panels to create a country mood in your kitchen, Cabinet Panel Insert Metal Tin Punched Star. Kitchen Cabinet Faux Panels. Customize new or existing kitchen cabinets by giving them the elegant look of raised faux- panel sides.

That’s why I love these 14-by-10-inch punched-tin cabinet panels from Irvin’s Country Tinware—they can transform any run-of-the-mill cabinet door into an instant slice of Americana. Antique vintage look ceiling. This classic diamond pattern is cut into tin with a rustic, coppery tint, which will look great against the warm tones of your logs. Offering the sale of panels , patterns, tools, accessories and kits for the do-it-yourself.

Nostalgic punched metal pie safe tins. Your Restoration Project Superstore Lowest Prices. A Great Starter Kit For Anyone Who Has a Crafty or Artistic Interest. Tin was an inexpensive, widely available material, and punching very tiny holes in it kept food aerated while keeping out dust and insects. Choose panel style (see Below) Small Upper Drawers.

Solid pine cabinet featuring a two panel punch tin door and thee shelves for hidden storage. Etsy is the home to thousands of handmade, vintage, and one-of-a-kind products and gifts related to your search. This is only for display purposes. No matter what you’re looking for or where you are in the worl our global marketplace of sellers can help you find unique and affordable options.

You searched for: punched tin panels ! These are not sold framed. The material is gauge metal. Back of Cabinet has finished Bead Board.

Crackled Porcelain Knobs with Roller catches keep doors shut. We have types of pie safe tins here: 1. Pie Safe Tin - Plain Tin -Coated. All of our punched tin panels are entirely hand crafted in Pennsylvania Amish country. Back it with thin cardboard for durability, then use tacks to secure the paper to both the metal and your work surface.

Brass and Copper panels $23. Save punched tin cabinet panels to get e-mail alerts and updates on your eBay Feed. Pricing for punched tin panels is: Steel ( tin ) panels any finish $11. Unfollow punched tin cabinet panels to stop getting updates on your eBay Feed. Pie safes from Creole Louisiana were typically crafted with punched tin panels for added ventilation and cooling.

There are numerous different pie safe styles, although many rely on the punched tin door panels for obvious reasons. A classic early American design. Paint the cabinet door and let dry. Measure the cabinet into which the punched tin panel will be set and use the tin snips to cut a tin sheet inch (cm) larger on all sides. Cut tin ceiling panels to fit the frame.

When dry, glue the panel to the wood base.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.